|

Wet Gas Corrosion Flow Loop #1

|

|

|

|

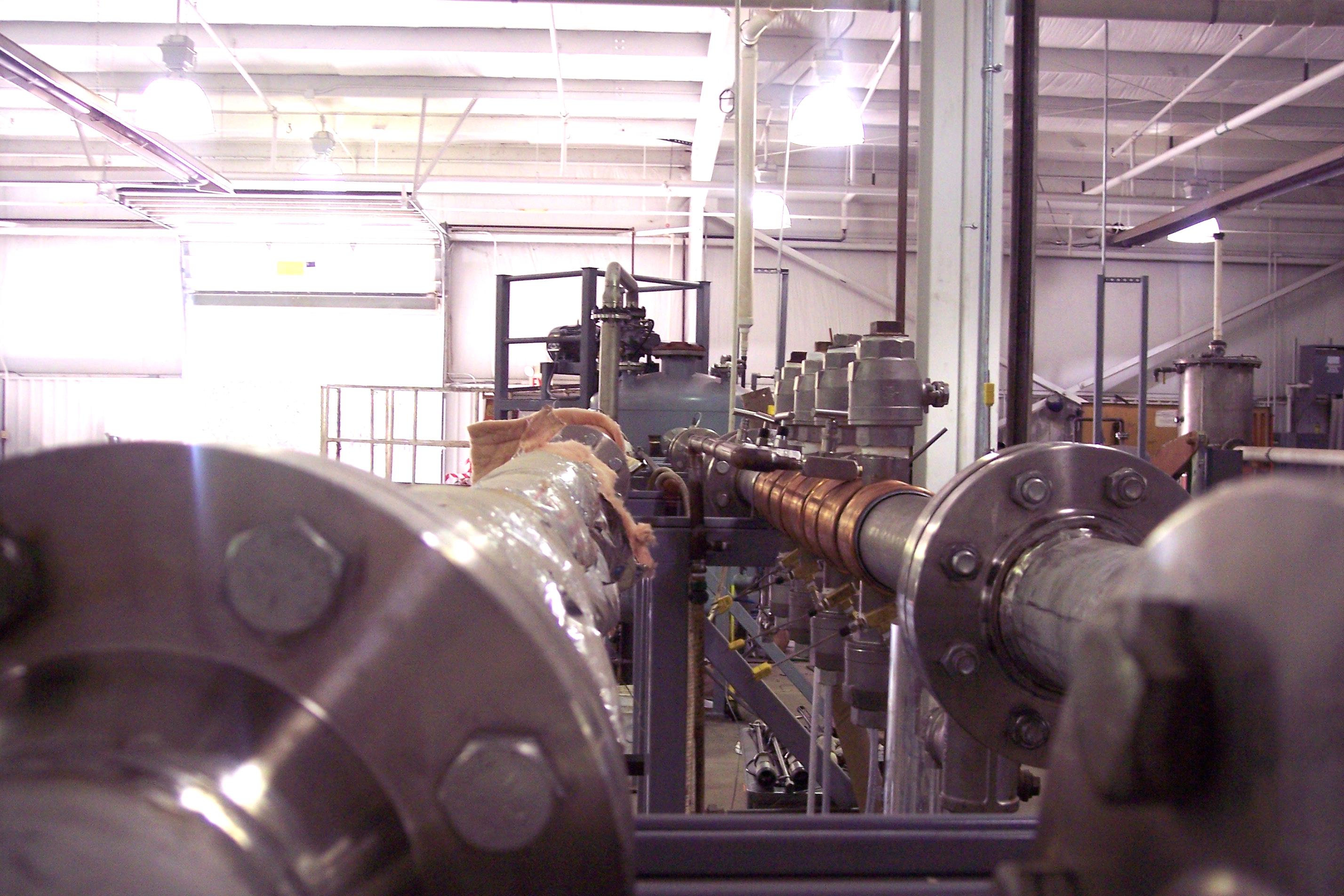

| Full View |

Test Section |

Blower |

Gas/Liquid Separator |

| Operational Conditions |

| Gas Velocity |

1 to 20 m/s |

| Partial pressure of Carbon Dioxide |

1 to 8 bar |

| Temperature range |

40°C to 90°C |

| Condensation rate |

0.02 to 3 ml/m2/s |

| Gas Mixtures |

Various mixtures of Nitrogen, Carbon Dioxide |

The Wet Gas Corrosion Flow Loop is designed to study the effect of operating parameters on the corrosion of carbon steel

under dewing condition during the transportation of wet gas. Several corrosive gases such as CO2 and HAc are under investigation.

This loop also provides a mean to quantify the efficiency of volatile inhibitors.

This closed system is comprised of 4" diameter, Sch 40, Stainless steel 316 for resistance to corrosion. It is 30 meters

long, horizontally leveled, and it is fully insulated from the ambiant. The tank used for liquid storage contains 1m3 of water. The

concentration of acid present in the water is controlled by injection. Heat is added to the system using resistance-heaters (Inconel© 625), which

are immersed in the tank. The power available is 90kW. A blower provides gas velocities up to 20 m/s. A system of cooling coils is used for the

cooling of the gaseous phase, allowing condensation to occur. A gas/liquid separator is used also to catch any liquid carry-over before the test

section. The test section provides 4 ports, 2 at the top of the line and 2 at the bottom of the line, which are available for the measurement of

the corrosion rate by insertion of flush-mounted corrosion monitoring probes.

Instrumentation

The temperature is controlled by a Proportional Integrator Differential (P.I.D) regulator (+/- 1°C). Monitoring of the

temperature occurs in the gas phase all around the 30-meter-long loop, between the inlet and the outlet of the heat exchangers (both in the gas

phase and in the cooling liquid), and at the wall temperature (by a thermocouple installed in the head of a flush-mounted probe). The pressure in

the tank is controlled (+/- 0.1 psi). The volume of condensed water is measured after being separated from the gas phase. Ceion Technology (E.R.

probes) is presently used to measure the corrosion rate in low conductivity-discontinuous condensed water

return to top

Wet Gas Corrosion Flow Loop #2

|

|

|

|

| Full View |

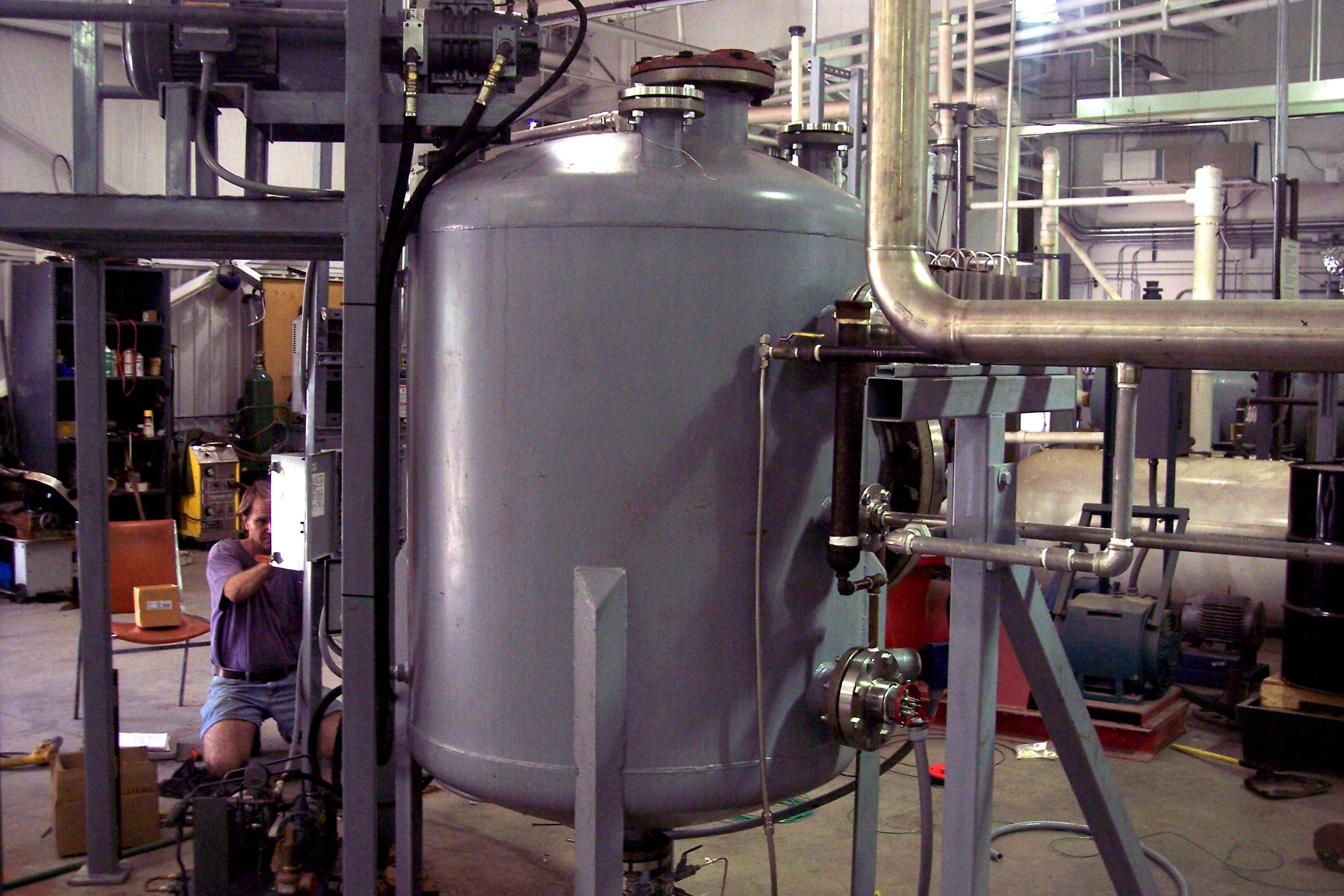

Tank and Blower |

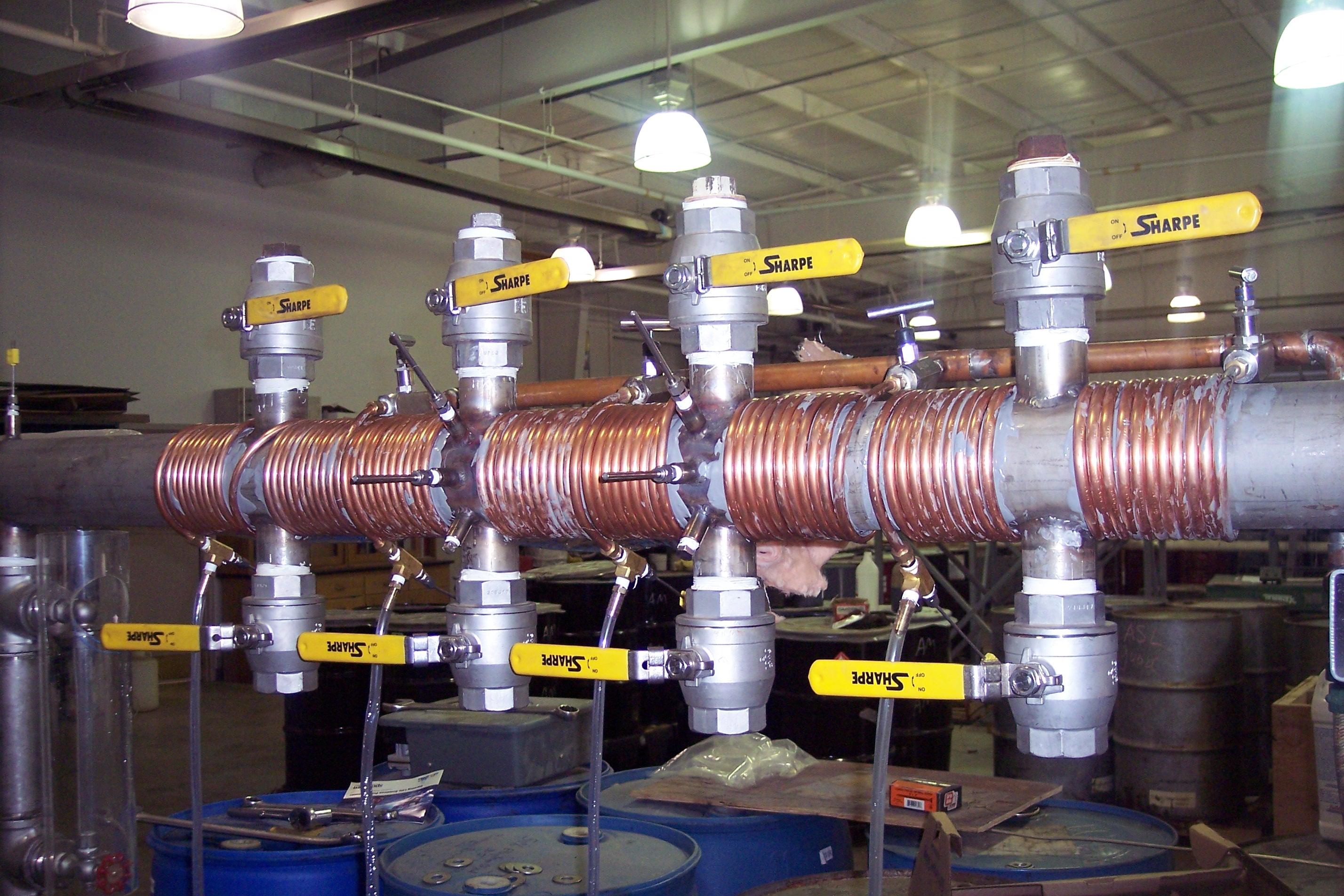

Test Section |

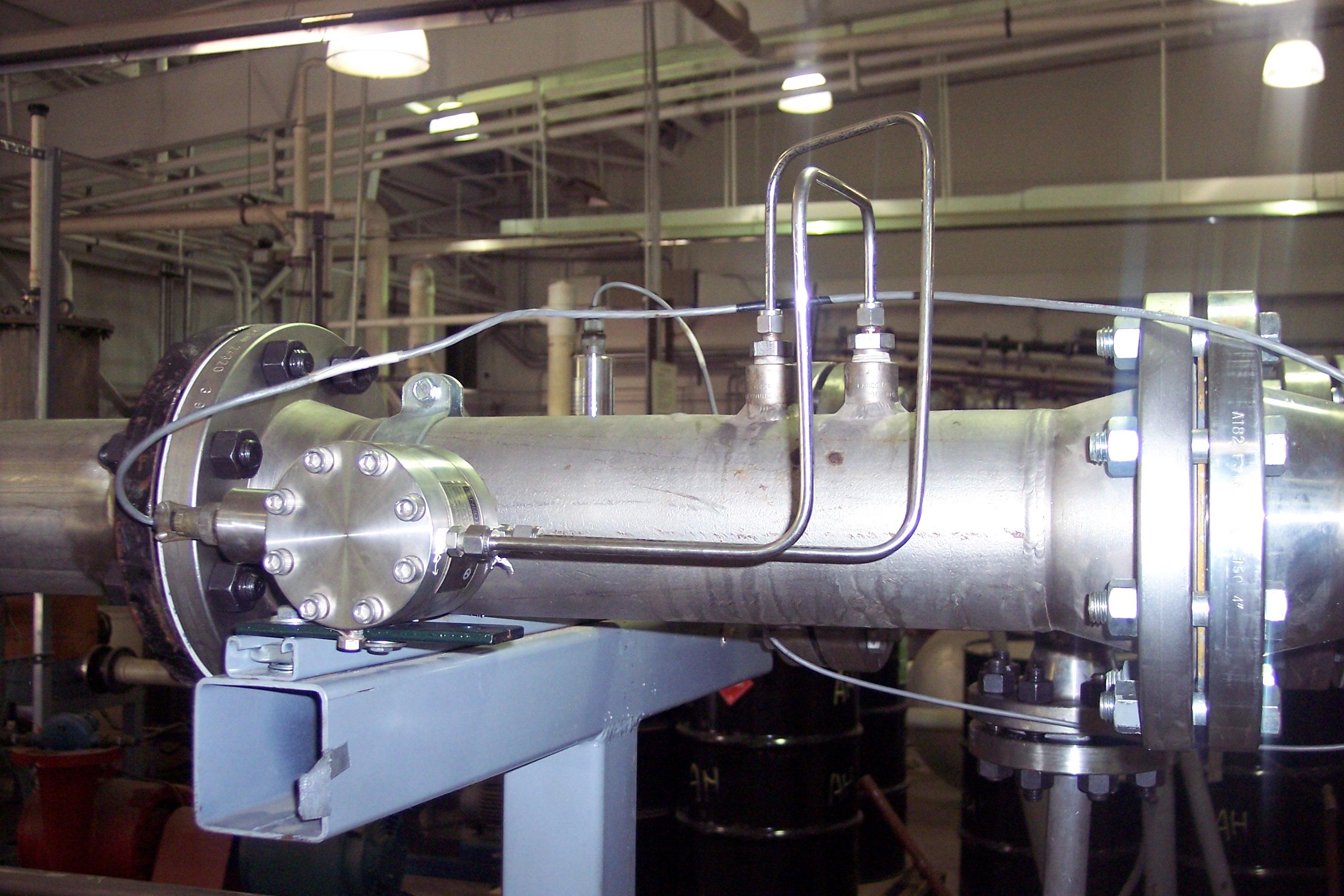

Gas Flow Meter |

| Operational Conditions |

| Gas Velocity |

1 to 12 m/s |

| Partial pressure of Carbon Dioxide |

1 to 7 bar |

| Temperature range |

40°C to 80°C |

| Condensation rate |

0.02 to 3 ml/m2/s |

| Gas Mixtures |

Various mixtures of Nitrogen, Carbon Dioxide |

The Wet Gas Corrosion Flow Loop #2 is designed to study the effect of operating parameters on the corrosion of carbon steel

under dewing condition during the transportation of wet gas. Several corrosive gases such as CO2 and HAc are under investigation. This

loop also provides a mean to quantify the efficiency of volatile inhibitors.

This closed system is comprised of 4" diameter, Sch 40, Stainless steel 316 for resistance to corrosion. It is 25 meters long,

horizontally leveled, and it is fully insulated from the ambiant. The tank used for liquid storage contains 1m3 of water. The

concentration of acid present in the water is controlled by injection. Heat is added to the system using resistance-heaters, which are immersed

in the tank. The power available is 11kW. A blower provides gas velocities up to 12 m/s. A system of cooling coils is used for the cooling of the

gaseous phase, allowing condensation to occur. The test section provides 8 ports, 4 at the top of the line and 4 at the bottom of the line, which

are available for the measurement of the corrosion rate by insertion of flush-mounted corrosion monitoring probes.

Instrumentation

The temperature is controlled by a Proportional Integrator Differential (P.I.D) regulator (+/- 1°C). Monitoring of the

temperature occurs in the gas phase all around the 25-meter-long loop, between the inlet and the outlet of the heat exchangers (both in the gas

phase and in the cooling liquid), and at the wall temperature (by a thermocouple installed in the head of a flush-mounted probe). Moreover, a

system of thermistors is installed at the test section in order to monitor the temperature of the gas, the inner wall and the outer wall (+/-

0.1°C). The pressure in the tank is controlled (+/- 0.1 psi). A gas flow meter is installed in line and is used to monitor and control the gas

velocity. The volume of condensed water is measured after being separated from the gas phase. Ceion Technology (E.R. probes) is presently used to

measure the corrosion rate in low conductivity-discontinuous condensed water.

[return to top]

|